Typically manifested as an enclosure, signal or coating, EMI shielding, also known as radiation shielding, is a service provided in order to prevent or block electromagnetic interference. Electromagnetic interference, commonly known as EMI is a kind of electromagnetic radiation that can damage, lessen or interrupt the functions of electronic devices and electronic equipment. EMI can travel along conductors, electrical circuits and wires. Similarly, radio frequency interference (RFI), which is radiated electromagnetic “noise,” travels through the air as radio waves, where it causes the same problems as EMI. Read More…

Sealing Devices is a leading North American distributor and fabricator of EMI shielding products, including conductive elastomers, Soft-Shield® low closure force gasketing, windows, conductive adhesives, formed-in-place parts, vents and elastomers.

We are one of the first in EMI technologies! Our roots trace back as early as the 1930s. We work hard to bring you the latest and greatest in EMI technologies and distribution. ADIT Electron Tubes manufactures low-level light detection systems and devices. Our photomultipliers are apart of a major international industry that we are a supplier of. Call us today for more information about our EMI...

FMS has been eliminating electromagnetic interference (EMI) and radio frequency interference (RFI) issues in commercial & industrial buildings, medical facilities, and research laboratories for over 25 years. Using the latest technology, backed by independent research and development, FMS delivers customized, innovative mitigation solutions for the most complex interference problems worldwide.

More EMI Shielding Companies

Applications

Radiation shielding serves critical roles across various industries, ensuring protection from ionizing radiation. In the medical field, it plays a pivotal role in radiology, radiation oncology, and nuclear medicine, shielding healthcare providers and patients from X-rays, gamma rays, and other radiation types during imaging, therapy, and diagnostics.

In the nuclear sector, radiation shielding is indispensable for safeguarding workers and the public. It’s integral to reactor design and infrastructure in nuclear power plants, controlling radiation release. Moreover, it’s essential during nuclear fuel handling, transport, and waste storage, ensuring the safe management of radioactive materials.

Radiation shielding also plays a pivotal role in various applications beyond Non-destructive testing (NDT). In industries spanning aerospace, manufacturing, and infrastructure, methods like radiography and computed tomography (CT) rely on it to verify the integrity of materials and components while safeguarding personnel from harmful radiation exposure.

Similarly, in industrial applications such as sterilization processes and material testing, radiation therapy necessitates shielding to shield operators and bystanders from radiation. For example, in the food industry, gamma irradiation ensures food preservation and safety, underscoring the critical need for robust shielding to protect both workers and consumers alike.

In the realm of space exploration, effective radiation shielding emerges as a critical necessity owing to the absence of Earth’s protective atmosphere. Whether in spacecraft or space habitats, robust shielding materials are indispensable for safeguarding astronauts against cosmic and solar radiation during extended missions.

Moreover, radiation shielding finds essential application in scientific research contexts, such as particle accelerators and laboratory experiments, where ionizing radiation is generated. These materials serve a crucial role in shielding researchers and equipment from potential radiation hazards.

It serves crucial roles beyond industrial and medical sectors, including security applications like screening systems in airports and ports. These systems utilize radiation sources for security scans, employing shielding to protect operators and the public.

Overall, radiation shielding is indispensable across a spectrum of industries, safeguarding individuals, workers, and the environment from ionizing radiation’s hazards. Its significance spans from medical and nuclear fields to aerospace, research, security, and beyond, underscoring its pivotal role in contemporary society.

Products Produced

Our EMI shielding services encompass a range of products, such as EMI enclosures, EMI coatings, filters, gaskets, RF filters, and conductive filters.

EMI Enclosure

EMI enclosures, known as Faraday cages, function by enveloping the equipment they shield. These enclosures can be solid or, if suitable for the application, made of perforated metal. The critical requirement is that the holes in the metal are smaller and more closely spaced than the electromagnetic waves they aim to block. To illustrate, think of a microwave oven where each wall is crafted from perforated metal sheets. These sheets prevent microwaves from escaping while permitting sufficient light to pass through for visibility.

EMI Coating

EMI coatings offer versatile shielding solutions by combining a carrier material with conductive metals like copper, chromium alloys, or nickel, creating a metallic ink. Service providers apply this coating by spraying it inside non-conductive enclosures, on wires, and within electronic device housings. Alternatively, EMI coatings can also be applied using brushing or painting methods.

EMI Filter

An EMI filter functions as a passive electronic component designed to mitigate electromagnetic interference (EMI) generated by nearby electronic devices and equipment. It effectively blocks unwanted non-radio frequency interference traveling through power lines and signals. Additionally, EMI filters can divert high-frequency EMI while allowing normal and lower frequencies to pass through. Typically, they are integrated into or connected near the switch or power source they are intended to protect, ensuring smoother operation of sensitive electronics.

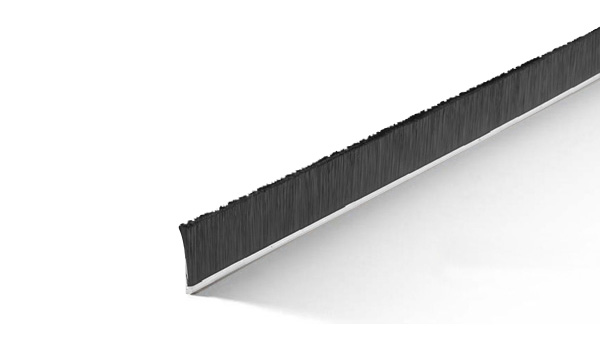

EMI Gasket

EMI gaskets combine electronically conductive rubber with EMI shielding metals to block electromagnetic interference (EMI) from entering or exiting enclosure gaps and seams. This advanced addition to the EMI shielding arsenal provides robust protection against the escalating strength of radio frequencies.

RF Absorber

RF absorbers, alternatively referred to as radar absorbers or microwave absorbers, specialize in safeguarding against RFI (Radio Frequency Interference). Their primary function involves absorbing electromagnetic energy to prevent its penetration into equipment.

Conductive Fabric

Conductive fabric, also known as metalized fabric, differs from traditional fabrics by incorporating metal into a fabric substrate (such as nylon or polyester) or using metal alone. Some varieties include an elastomer core to enhance compression and deflection capabilities. Conductive fabric can be knitted, woven, or nonwoven, with knitted metal wire mesh being a popular example. Its applications are varied: it can serve as a protective tapestry for entire rooms or be cut into gaskets for specific uses.

History

EMI shielding traces its origins to the Faraday cage, named after Michael Faraday who built the first prototype in 1836. This innovation was inspired by Benjamin Franklin’s earlier discovery in 1755 that electric charges could be blocked. Faraday constructed a room entirely coated with metal foil to demonstrate this principle. Using an electrostatic generator, he discharged high voltages outside the room, confirming that the interior walls remained free from any electric charge, validating his hypothesis.

About a century later, as radio technology gained widespread adoption, concerns over Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) began to grow. Recognizing the need to address these issues, the International Electrochemical Commission (IEC) convened in Paris and proposed the formation of CISPR (International Special Committee on Radio Interference). Established as the pioneering regulatory body in this field, CISPR laid the groundwork for many of today’s Electromagnetic Compatibility (EMC) regulations.

In 1979, the United States initiated the enforcement of EMI regulations, with the European Union following suit in the mid-1980s. Since then, the prevalence of EMI and RFI has expanded significantly alongside the proliferation of electronic devices, which have become more sensitive to electromagnetic noise than ever before. To meet the growing demand for effective EMI shielding, scientists and engineers have developed stronger shielding materials capable of fitting into smaller and more intricate spaces.

Materials Process

There exists a vast array of materials utilized for EMI and RFI Shielding. Typically, the shielding process necessitates a conductive surface, predominantly employing metals. These metals must possess high magnetic permeability and excellent magnetic energy absorption. Common shielding materials include copper, steel, steel alloys, aluminum, and nickel, with MuMetal® being the industry-preferred alloy.

Likewise, EMI enclosures are often crafted from solid or perforated stainless steel, nickel, copper alloys, or aluminum. Gaskets, typically die-cut from electrically conductive rubber materials, are commonly affixed to EMI shields.

Copper

Copper stands out as a superb and widely used material for magnetic shielding. It is highly prized by shielding providers for its exceptional ability to block and diminish electromagnetic interference (EMI) and radio frequency interference (RFI), coupled with its remarkable malleability. The primary downside lies in its higher cost compared to alternative materials.

Steel

Steel is renowned for its robustness and longevity. When used as a shielding material, its permeability becomes particularly prized, enabling effective blocking of low-frequency EMI. This attribute is especially notable in stainless steel and carbon steel varieties.

Aluminum

Aluminum is highly prized in EMI shielding for its non-ferrous nature, lightweight properties, and excellent conductivity.

Nickel

Nickel, a favored shielding material, is prized for its magnetic properties, durability, hardness, and electrical conductivity. Its versatility allows for various applications: it can serve as a standalone shield or be integrated into alloyed materials for electromagnetic shielding purposes.

MuMetal®

MuMetal®, an alloy amalgamating iron, copper, nickel, and molybdenum, stands out for its unparalleled capacity in minimizing EMI/RF interference. Renowned for its exceptionally high magnetic permeability, it leads the field in shielding effectiveness.

Conductive Rubber

Conductive rubbers like silicone and neoprene are essential for EMI/RFI shielding. Silicone stands out for its exceptional flexibility, tensile strength, and resilience across various temperature extremes. In contrast, neoprene excels in compression strength and overall utility.

How It Works

EMI shielding functions by utilizing conductive or magnetic substances to construct a physical barrier. This barrier intercepts and redirects electromagnetic waves, safeguarding sensitive electronic components or circuits. Typically composed of metals such as copper, aluminum, or steel, these materials possess the capability to absorb, reflect, or disperse electromagnetic energy. By enveloping electronic devices or circuitry with EMI shielding, they form a conductive enclosure that effectively blocks incoming electromagnetic radiation. External electromagnetic interference is thwarted by the shield, either absorbed or redirected to avoid disrupting operations. Internally, electronic devices utilize EMI shielding to isolate circuits, ensuring signals remain intact. This shielding creates a controlled environment that neutralizes unwanted electromagnetic radiation, preserving electronics’ reliability amid electrical noise.

Design Considerations

Manufacturers developing EMI shielding devices must carefully assess key factors throughout the design phase to ensure the shielding’s efficacy and suitability for specific applications. Foremost, determining the necessary shield effectiveness or attenuation level is critical to effectively mitigate electromagnetic interference (EMI). This assessment hinges on the sensitivity of the electronics and the prevailing EMI/RF strength in the environment.

Additionally, the scope and dimensions of the application are pivotal. Different scenarios necessitate varied forms of EMI shielding, ranging from gaskets, tapes, and coatings to comprehensive enclosures. Manufacturers must customize the shielding solution to align precisely with the application’s unique demands, considering factors such as space availability, weight limitations, and installation convenience.

Flexibility is crucial, particularly when shielding must conform to irregular shapes or varied contours of devices or equipment. In scenarios involving mechanical stresses or movements, the shielding needs to remain adaptable without compromising its effectiveness.

Adherence to industry-specific standards and regulations is equally critical. Manufacturers must comply with relevant EMI/EMC standards, such as those mandated by the Federal Communications Commission (FCC) in the United States, the European Union’s Conformité Européenne (CE) marking, or CISPR standards. This ensures that the shielding meets established performance criteria and avoids interference with other devices.

Device or equipment sensitivity plays a critical role in EMI shielding design. Certain devices are extremely vulnerable to electromagnetic interference, necessitating more robust shielding solutions with higher levels of attenuation to ensure sufficient protection.

Furthermore, the selection of materials is pivotal in EMI shielding strategies. Whether opting for conductive or magnetic materials depends on various factors such as the frequency spectrum of the interference and the desired shielding efficacy. Additionally, considerations like cost-effectiveness, durability, and environmental impact also impact the choice of materials.

Achieving effective EMI shielding design requires a thorough evaluation of the application’s unique requirements, sensitivity of the device, adherence to industry regulations, and customization of the shielding solution to ensure ideal electromagnetic interference protection, balancing flexibility, size, and shielding effectiveness.

Variations and Similar Services

An alternative to EMI shielding is vacuum metallization, a process where conductive metal is deposited onto a substrate. In this method, manufacturers heat metal within a vacuum chamber until it vaporizes. The metal vapor then condenses on the substrate, creating a protective layer once it dries.

Benefits

EMI shielding offers customers a myriad of benefits, including safeguarding health, enhancing equipment performance, ensuring durability, and promoting sustainability.

Health

EMI shielding provides a crucial advantage by safeguarding humans from exposure to electromagnetic interference (EMI), which can lead to various health issues. These problems range from minor discomforts to severe conditions, including tingling sensations, tissue heating, eye damage, and burns. Furthermore, there is apprehension regarding the potential long-term consequences of EMI/RFI exposure, such as an increased risk of cancer.

Performance

EMI/RF shielding services not only enhance the performance of your electrical devices and equipment by preventing malfunctions, but they also boost efficiency and reduce degradation over time.

Durability

Over time, EMI shielding demonstrates its enduring value, becoming increasingly advantageous as it endures.

Sustainability

EMI/RF shielding, beyond just coatings, can be recycled. This not only supports sustainability efforts but also helps reduce your expenses.

Things to Consider

EMI shielding is indispensable, and finding a top-notch service provider is crucial. In today’s saturated market, identifying the ideal EMI shielding provider can be challenging.

But you’re in luck. Here, we’ve curated a selection of highly knowledgeable, skilled, and customer-focused EMI shielding companies. Our comprehensive list includes detailed company profiles, contact information, and website links. Each listed provider excels in manufacturing and supplying electromagnetic shielding products, though not every one may perfectly suit your requirements. To navigate your search effectively, we recommend visiting each company’s website to explore their offerings thoroughly. Choose three or four that stand out to you, and initiate individual conversations with them. Discuss your specific needs in detail, covering aspects like lead times, budget considerations, and compliance requirements.

After these discussions, select the provider that best aligns with your requirements. Reach out for a quote or schedule a call to start your project with confidence.

Check out our Clean Rooms website

Check out our Magnets website

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services