Radiation shielding, often referred to as electromagnetic interference (EMI) shielding, is a crucial process employed to safeguard sensitive equipment and human health from the harmful effects of electromagnetic radiation. It encompasses the use of specific materials and techniques to block, absorb, or reflect electromagnetic waves. Read More…

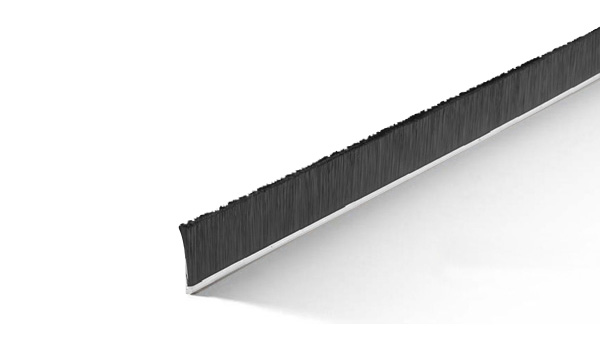

Sealing Devices is a leading North American distributor and fabricator of EMI shielding products, including conductive elastomers, Soft-Shield® low closure force gasketing, windows, conductive adhesives, formed-in-place parts, vents and elastomers.

We are one of the first in EMI technologies! Our roots trace back as early as the 1930s. We work hard to bring you the latest and greatest in EMI technologies and distribution. ADIT Electron Tubes manufactures low-level light detection systems and devices. Our photomultipliers are apart of a major international industry that we are a supplier of. Call us today for more information about our EMI...

FMS has been eliminating electromagnetic interference (EMI) and radio frequency interference (RFI) issues in commercial & industrial buildings, medical facilities, and research laboratories for over 25 years. Using the latest technology, backed by independent research and development, FMS delivers customized, innovative mitigation solutions for the most complex interference problems worldwide.

More Radiation Shielding Companies

Creating EMI Shielding

Several processes are employed to create effective EMI shielding. Coating and plating involve applying conductive materials such as metals to the surface of electronic devices, forming a protective shield that blocks external electromagnetic interference. Enclosures and housings, another method, provide a physical barrier around equipment to shield against electromagnetic radiation. Filtering and grounding techniques help minimize electromagnetic interference in power lines and communication systems, ensuring smooth and reliable operation. Additionally, absorption and reflection techniques are used to create controlled environments, vital for sensitive experiments or medical imaging facilities.

Materials for Radiation Shielding

Various materials are utilized for radiation shielding, each with its unique properties and applications. Lead, due to its high density and atomic number, is commonly employed for shielding against X-ray and gamma ray radiation in medical facilities. Copper, renowned for its excellent electrical conductivity, is frequently used to shield sensitive electronic components from EMI. Aluminum, lightweight and corrosion-resistant, finds applications in electronic enclosures and aerospace industries. Carbon-based materials such as conductive foams and composites offer both shielding and mechanical properties, making them suitable for aerospace and military applications.

Considerations Regarding Radiation Shielding

While radiation shielding plays a vital role in protecting against electromagnetic interference, there are certain considerations to be aware of including the impact on weight, cost, and structural design of items, particularly in industries where weight restrictions are critical, such as aerospace. Additionally, some materials used for shielding may pose environmental and health risks.

Manufacturers Address These Considerations

Manufacturers of radiation shielding are actively addressing these considerations. To start, they are focusing on the development of lightweight materials and innovative designs that offer effective shielding while minimizing weight and structural impact. Furthermore, there is a growing emphasis on eco-friendly and sustainable alternatives to traditional shielding materials, ensuring the safety of both users and the environment.

Benefits of Radiation Shielding

Radiation shielding provides numerous benefits across various industries. By minimizing electromagnetic interference, it helps ensure the reliable operation of sensitive electronic devices, preventing disruptions and data loss. It also plays a critical role in protecting human health and safety by reducing exposure to harmful radiation. Moreover, radiation shielding preserves the integrity and functionality of electronic equipment, prolonging their lifespan and reducing maintenance costs.

Applications of Radiation Shielding

Radiation shielding finds extensive applications in different sectors. In the medical field, for example, radiation shielding is indispensable in X-ray rooms and cancer treatment centers. It shields patients, medical professionals, and visitors from the harmful effects of radiation, ensuring their safety while enabling accurate diagnoses and effective therapies. Without radiation shielding, medical procedures that rely on X-ray imaging or radiation-based treatments would be compromised, jeopardizing patient care and outcomes.

The aerospace and aviation industry also heavily relies on radiation shielding to protect aircraft and satellites. Cosmic radiation and electromagnetic interference pose significant risks to sensitive electronic components and communication systems onboard. By implementing effective shielding measures, aerospace engineers ensure the integrity and functionality of critical systems, enhancing the safety and reliability of air travel and space exploration.

In electronics manufacturing and testing, meanwhile, radiation shielding is paramount to guarantee the accuracy and reliability of electronic devices. Shielding measures are employed to prevent external electromagnetic interference that could disrupt signal transmission or compromise the performance of delicate components. Whether it's the production of consumer electronics or intricate industrial systems, radiation shielding plays a vital role in maintaining product quality and operational efficiency.

Nuclear power plants and research facilities also rely on radiation shielding to ensure the safety of workers and the environment. Shielding measures are employed to contain and control radioactive emissions, preventing their harmful effects from spreading beyond designated areas. By implementing robust shielding protocols, the nuclear industry maintains stringent safety standards, safeguarding both personnel and surrounding communities from radiation hazards.

Finally, defense and military applications also benefit greatly from radiation shielding. Sensitive electronic equipment and communication systems must operate reliably in challenging and potentially hostile environments. By integrating radiation shielding into their designs, manufacturers protect against electromagnetic interference, ensuring secure and uninterrupted communication, as well as the effectiveness of critical military systems.

Choosing the Right Radiation Shielding Manufacturer

To ensure you have the most positive outcome when purchasing radiation shielding from a radiation shielding manufacturer, it is important to compare several companies using our directory of radiation shielding manufacturers. Each radiation shielding manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each radiation shielding business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple radiation shielding companies with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services