Available as stress annealed (partially annealed for ease of machinability) sheet stock is used for fabricated shields such as enclosures, cylinders, cans, channels or 3D boxes. Typically, atmospherically controlled annealing is required after stamping, machining, bending, rolling or welding to provide maximum shielding performance. Read More…

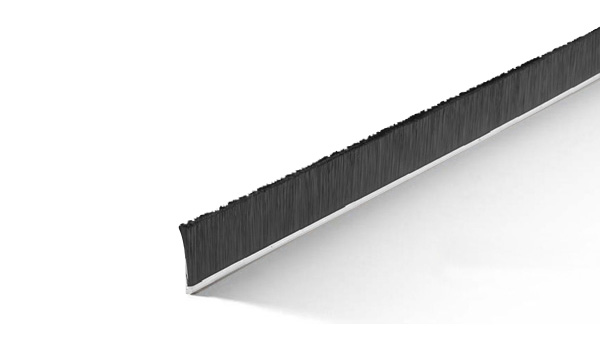

Sealing Devices is a leading North American distributor and fabricator of EMI shielding products, including conductive elastomers, Soft-Shield® low closure force gasketing, windows, conductive adhesives, formed-in-place parts, vents and elastomers.

We are one of the first in EMI technologies! Our roots trace back as early as the 1930s. We work hard to bring you the latest and greatest in EMI technologies and distribution. ADIT Electron Tubes manufactures low-level light detection systems and devices. Our photomultipliers are apart of a major international industry that we are a supplier of. Call us today for more information about our EMI...

FMS has been eliminating electromagnetic interference (EMI) and radio frequency interference (RFI) issues in commercial & industrial buildings, medical facilities, and research laboratories for over 25 years. Using the latest technology, backed by independent research and development, FMS delivers customized, innovative mitigation solutions for the most complex interference problems worldwide.

More MuMetal® Companies

MuMETAL® Stress Annealed alloy is available in many forms, but most shields are fabricated from our sheet stock in gauges from .014" to .062" thickness [0,36mm to 1,57mm]. MuMETAL® Foil is fully annealed and available in stock guages from .002" to .010" thickness [0,05mm to 0,25mm].

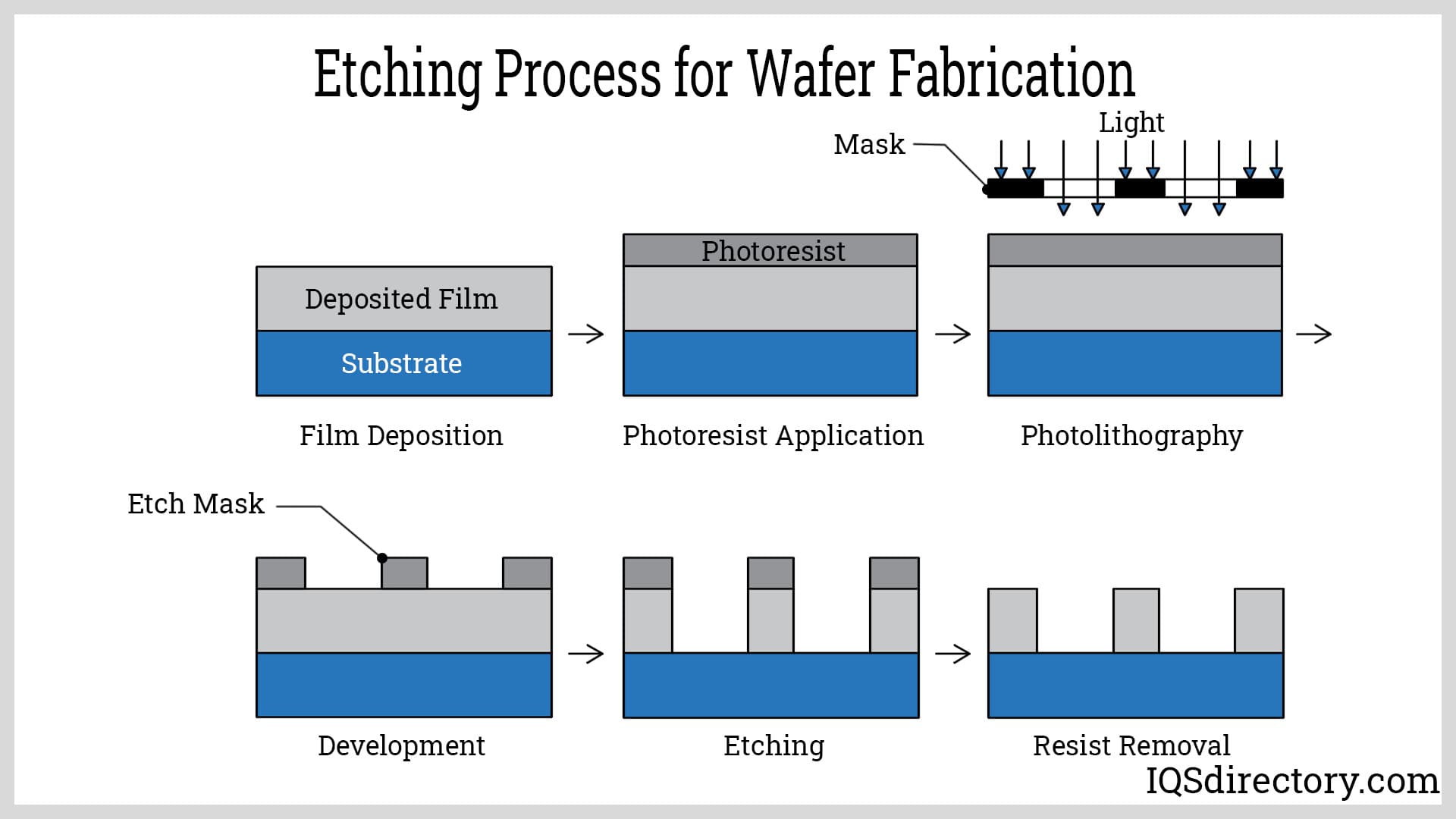

MuMETAL® is typically stocked in a stress annealed state to allow further fabrication, stamping, severe forming or welding. During fabrication, a material’s grain structure is weakened. After final fabrication processes are completed, grain structure is then modified by controlled atmospheric annealing to relieve stress in the material, resulting in larger grain structure, softer temper, and ultimate shielding performance.

Although MuMETAL® is available in many forms, most shields are fabricated from foil or sheet stock.

When your shield design requires severe forming, stamping and/or welding, specifying MuMETAL® on your drawings insures you will receive the highest level of initial permeability and shielding efficiency available. And, MuMETAL® is formulated and manufactured to exacting standards which allow consistent fabrication and final anneal.

Not only does Magnetic Shield Corporation offer MuMETAL® alloy, we can provide a full range of manufacturing services. From your drawing or sketch, we can waterjet, laser, EDM, shear, slit, punch, blank, stamp, chemical etch, form, bend, roll, spot-weld, heliarc weld, and/or laser weld. Using MuMETAL® alloy, we can produce complete magnetic shields, to your drawings or specifications.

MuMetal is a Registered Tradmark of Magnetic Shield Corporation.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services