Electromagnetic shielding is important to protect delicate mechanical equipment from electromagnetic radiation. Many machines and industrial tools generate electromagnetic radiation that can damage the operation of other equipment. Computer equipment is at the highest risk for electromagnetic damage, but other machines that use automated and electrical circuits can also be damaged with exposure to too much electromagnetic radiation.

Most electromagnetic shielding products available on the market today include some sort of metal coating that help reflect the electromagnetic radiation away from the delicate components of the machine. Companies have used metal boxes, metal shields, and even metal-based tape to help protect the components of a system.

The problem with metal-based shielding is that it is heavy and bulky. Many machines and circuits could be protected with much smaller shields if another material aside from metal could be used.

Luckily, science and technology is merging and there are now electromagnetic shielding products available that do not require the use of large, bulky metal pieces. One of the newest forms of shielding is polyurethane-based. This flexible coating can be applied to nearly any electrical component to keep it safe.

The way that the polyurethane coating works is with the inclusion of silver inside the plastic mixture. The addition of silver gives the plastic the same electromagnetic shielding properties as a solid piece of metal- just with a much smaller profile. Companies can apply the thin plastic coating over individual pieces and components that they need protected rather than installing a large box protecting the entire system.

This not only helps save space and eliminate waste inside a factory, but it is also less expensive and much lighter than traditional electromagnetic shielding options. Companies can install the plastic shielding for much less than the cost of full metal systems.

Most electromagnetic shielding products available on the market today include some sort of metal coating that help reflect the electromagnetic radiation away from the delicate components of the machine. Companies have used metal boxes, metal shields, and even metal-based tape to help protect the components of a system.

The problem with metal-based shielding is that it is heavy and bulky. Many machines and circuits could be protected with much smaller shields if another material aside from metal could be used.

Luckily, science and technology is merging and there are now electromagnetic shielding products available that do not require the use of large, bulky metal pieces. One of the newest forms of shielding is polyurethane-based. This flexible coating can be applied to nearly any electrical component to keep it safe.

The way that the polyurethane coating works is with the inclusion of silver inside the plastic mixture. The addition of silver gives the plastic the same electromagnetic shielding properties as a solid piece of metal- just with a much smaller profile. Companies can apply the thin plastic coating over individual pieces and components that they need protected rather than installing a large box protecting the entire system.

This not only helps save space and eliminate waste inside a factory, but it is also less expensive and much lighter than traditional electromagnetic shielding options. Companies can install the plastic shielding for much less than the cost of full metal systems.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

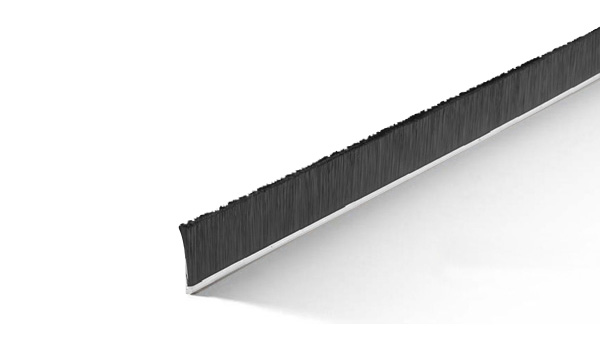

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services