Radio frequency interference, or RFI, is radiated electromagnetic “noise,” which travels through the air as radio waves. RFI shielding is a process where interference from external electromagnetic signals is reduced on electronic devices. These external electromagnetic signals are capable of disrupting the function of electronic devices. Engineers create effective RFI shields by selecting materials that attenuate the strength of an electromagnetic signal and placing them around the device’s sensitive areas. Read More…

Sealing Devices is a leading North American distributor and fabricator of EMI shielding products, including conductive elastomers, Soft-Shield® low closure force gasketing, windows, conductive adhesives, formed-in-place parts, vents and elastomers.

We are one of the first in EMI technologies! Our roots trace back as early as the 1930s. We work hard to bring you the latest and greatest in EMI technologies and distribution. ADIT Electron Tubes manufactures low-level light detection systems and devices. Our photomultipliers are apart of a major international industry that we are a supplier of. Call us today for more information about our EMI...

FMS has been eliminating electromagnetic interference (EMI) and radio frequency interference (RFI) issues in commercial & industrial buildings, medical facilities, and research laboratories for over 25 years. Using the latest technology, backed by independent research and development, FMS delivers customized, innovative mitigation solutions for the most complex interference problems worldwide.

More RFI Shielding Companies

The Principle of RFI Shielding

There are many RFI producers and RFI-sensitive products in the average household. However, RFI is a problem because the frequency range interferes with the functions of nearby equipment and devices. As an example, radio signals can be blocked in military initiatives by RFI. As a result, these signals can compromise entire missions.

Almost every electronic device can produce RFI, but the most common producers of RFI are motors, relays, processors, computers, industrial controllers, and high-tech medical devices. Electronic shielding gasket are capable of protecting against RFI. In addition, many shielding gaskets are designed to provide complete shielding from radio frequency interference.

These shielding products are available in many shapes, sizes, mounts, materials, and seal types. Protecting modern electronic equipment from radio frequency interference with RFI shielding is very important to improve effectiveness. This is achieved by the simple addition of a shielding gasket. There are many custom-shielding gaskets on the market.

Types of RFI Shielding

The different types of RFI Shielding include:

Metalized Conductive Foam Gaskets

Metalized Conductive Foam gaskets include nickel-copper plated polyurethane foam sandwiched between the electrically conductive polyester fabric. The metalized conductive foam core performs better at higher frequencies than conventional perimeter-conductive products, mostly at higher frequencies.

Flexible Ferrite Sheets and Magnetic Shielding Materials

These sheets are manufactured by thin, highly porous sintered ferrite with PET film and adhesive tape. Magnetic shielding materials are mostly used for near-field communication, radio frequency identification, and wireless charging applications. They are manufactured in standard ferrite layer thickness sheets and gaskets cut to the requirements.

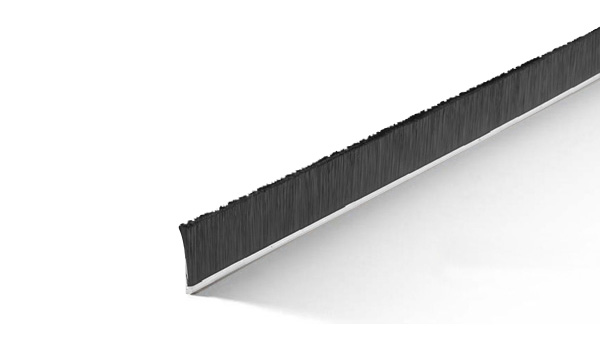

Spring Finger Contact Strips

Spring finger contact strips are manufactured in stainless steel or beryllium copper. They come in standard coils or lengths and are used for frequent access door seals. They are also used on lids ranging from small hand-held devices to room-sized enclosures.

RFI Absorbers WAM

RFI Absorbers WAM is made from magnetic particles in a polymer resin for producing a composite absorber material. They are manufactured in sheet form or cut gaskets. They reduce RFI noise within enclosures by attaching to flexible connectors, cables, or positioning near LCD.

Board Level Shields

Board-level shields are manufactured as one-piece and two-piece surface mount shields. They minimize crosstalk, provide isolation of board-level components, and they reduce susceptibility without impacting system speed.

Conductive Silicone Elastomer

Conductive silicone elastomer is made from a range of fillers in a silicone elastomer. They are manufactured in sheet form and custom die-cut shapes, gaskets, O-rings, etc.

Conductive Fabric over Foam Gaskets

Conductive fabrics are coated fabrics wrapped over a soft sponge core (the foam gasket). They provide excellent conductivity as well as efficient shielding. They are supplied in the form of custom gaskets or shaped profile strips. They are used on panels, doors, chassis, and enclosures.

Conductive Cloth

Conductive Cloth offers good conductivity and a shielding effect. In addition, they provide high friction, abrasion resistance, and good metal binding.

Applications of RFI Shielding

Almost every industry that uses or produces electronic devices prone to electromagnetic interference can utilize RFI shielding. These industries have direct interests in reducing interference from external signals. These interfering signals have potential complications that range from the low-quality audio transmission to the complete failure of a rail control system. Many industries rely on RFI shielding, including:

- Medical technology

- Electric vehicles

- Satellites and telecommunications

- Military and defense

- Aerospace

Benefits of RFI Shielding

RFI shielding tapes can:

- Reduce signal interactions that cause communication problems.

- Be cost-effective and highly versatile.

- Be customized to fit any unique shielding application.

- Ensure optimal performance of equipment.

- Ensure the safety of equipment in a broad range of industries.

Choosing the Right RFI Shielding Supplier

To ensure the most positive outcome when purchasing RFI shielding from a RFI shielding supplier, it is important to compare several companies using our directory of RFI shielding suppliers. Each RFI shielding company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each RFI shielding business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple FRI shielding companies with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services