Our world is filled with highly technical devices that rapidly accomplish tasks that use to take hours and days. Society depends on these essential instruments to organize data and retain necessary information. Read More…

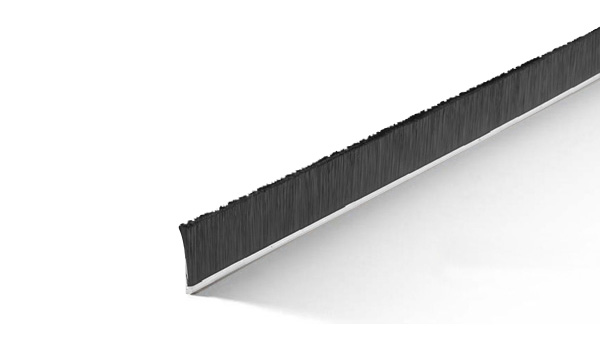

Sealing Devices is a leading North American distributor and fabricator of EMI shielding products, including conductive elastomers, Soft-Shield® low closure force gasketing, windows, conductive adhesives, formed-in-place parts, vents and elastomers.

We are one of the first in EMI technologies! Our roots trace back as early as the 1930s. We work hard to bring you the latest and greatest in EMI technologies and distribution. ADIT Electron Tubes manufactures low-level light detection systems and devices. Our photomultipliers are apart of a major international industry that we are a supplier of. Call us today for more information about our EMI...

FMS has been eliminating electromagnetic interference (EMI) and radio frequency interference (RFI) issues in commercial & industrial buildings, medical facilities, and research laboratories for over 25 years. Using the latest technology, backed by independent research and development, FMS delivers customized, innovative mitigation solutions for the most complex interference problems worldwide.

More Steel Shielding Companies

Steel EMI Shielding –

In the midst of all of this electronic activity are random electrical signals that pass through the air and can cause serious damage to our devices. To protect equipment, it is important to have some form of blockage that can prevent the random signals from damaging or destroying vital equipment. The best form of protection is EMI steel shielding.

The random electrical pulses that float through the air are called electromagnetic interference (EMI). Steel shielding is designed to either absorb or resist EMI’s and is best form of shielding since it can deflect or absorb stray electrons. Steel is a very durable metal that has many features, which makes it a perfect solution for protecting technical equipment.

A critical factor in the battle against EMI’s is corrosion, which can interrupt electrical signals and permanently damage equipment. Of the many forms of shields on the market, steel shielding, with an added alloy such as zinc, tin or aluminum, is exceptional in avoiding and preventing corrosion. The dangers associated with corrosion are not normally seen until it has already destroyed equipment.

An additional factor that makes steel shielding attractive is its ability to be soldered. The various forms of shields include cabinets and cases that can hold racks. Steel shielding can be seamlessly soldered and formed to any size for these types of enclosures. The tight seal between connections does not interrupt the protective quality of the steel shielding.

For the best protection, shields need to be assembled in layers since single layered shields do not have sufficient protective capabilities. Steel shielding is produced in multiple thicknesses that makes it capable of being formed into layers in the production process.

The most impressive aspect of steel shielding is its low conductivity making it a perfect choice for a shield designed to prevent the passage of electrons. Its density absorbs electromagnetic interference and sends it to a ground material. The process is completed efficiently without the need for any concern on the part of the user.

There are many forms of shields on the market that may have attractive selling points. For the most economical and cost-efficient choice, steel shielding is far superior to any of the other materials available.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services