Wire shielding is a crucial aspect of modern electrical systems, providing protection against electromagnetic interference (EMI) and radio frequency interference (RFI). It is a combination of both a process and materials designed to safeguard wires and cables from external disturbances. By minimizing the impact of interference, wire shielding ensures optimal performance and reliability in a wide range of applications. Read More…

Sealing Devices is a leading North American distributor and fabricator of EMI shielding products, including conductive elastomers, Soft-Shield® low closure force gasketing, windows, conductive adhesives, formed-in-place parts, vents and elastomers.

We are one of the first in EMI technologies! Our roots trace back as early as the 1930s. We work hard to bring you the latest and greatest in EMI technologies and distribution. ADIT Electron Tubes manufactures low-level light detection systems and devices. Our photomultipliers are apart of a major international industry that we are a supplier of. Call us today for more information about our EMI...

FMS has been eliminating electromagnetic interference (EMI) and radio frequency interference (RFI) issues in commercial & industrial buildings, medical facilities, and research laboratories for over 25 years. Using the latest technology, backed by independent research and development, FMS delivers customized, innovative mitigation solutions for the most complex interference problems worldwide.

More Wire Shielding Companies

Varieties of Wire Shielding and Their Applications

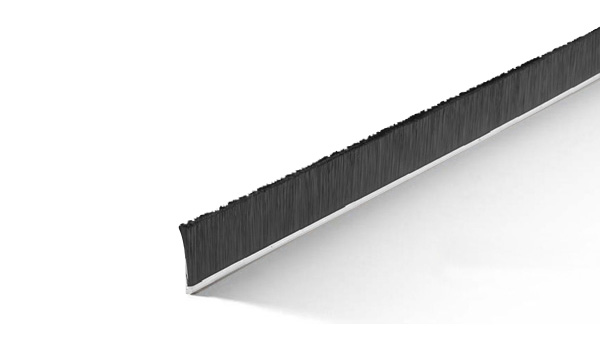

There are several varieties of wire shielding, each tailored to specific requirements. Foil shielding, for instance, involves wrapping a thin metal layer around the wire, making it suitable for applications such as audio cables and electronic circuits. Braided shielding, on the other hand, employs a mesh of woven metal wires to provide flexibility and durability, making it ideal for coaxial cables and high-frequency signal transmission. Spiral shielding, consisting of a helical arrangement of metal wires, finds applications in data cables and telecommunications. Additionally, conductive polymer shielding, which utilizes specially formulated polymers with conductive properties, offers unique benefits, making it a preferred choice for demanding industries like medical devices and aerospace.

Considerations Regarding Wire Shielding

While wire shielding provides significant advantages, it does have some considerations. Electrostatic interference and magnetic interference can still affect shielded wires, albeit to a lesser extent. Additionally, wire shielding can add bulk and weight to the cables, making it challenging to accommodate in space-constrained applications. Moreover, the use of specialized materials and manufacturing processes for wire shielding can contribute to increased costs.

Manufacturer Efforts to AddressThese Considerations

Recognizing these considerations of wire shielding, manufacturers have undertaken various initiatives to overcome these challenges. Improved shielding materials with advanced properties and enhanced performance characteristics are being developed. Innovative techniques, such as precision engineering and optimized shielding geometries, are also being employed to maximize efficiency while minimizing size and weight. Additionally, manufacturers are working on cost optimization strategies, leveraging economies of scale and exploring alternative materials without compromising the shielding effectiveness.

Benefits of Wire Shielding

Despite these considerations, wire shielding offers numerous benefits that outweigh the challenges. First and foremost, it mitigates EMI and RFI, ensuring the integrity of signal transmission and reducing signal degradation. This enhanced signal quality leads to improved data transfer rates and fewer errors. Wire shielding also enhances reliability and performance by protecting against external disturbances, resulting in more robust and stable operation. Moreover, adherence to regulatory standards and industry certifications is facilitated through the implementation of wire shielding, ensuring compliance and reducing potential legal or safety issues.

Standards and Certifications for Wire Shielding

Regulatory standards and industry certifications pertaining to wire shielding ensure that manufacturers adhere to specific guidelines and requirements to guarantee the quality and effectiveness of their shielding solutions. These standards are typically developed and maintained by organizations and regulatory bodies such as the International Electrotechnical Commission (IEC), the Institute of Electrical and Electronics Engineers (IEEE), and regional regulatory agencies like the Federal Communications Commission (FCC) in the United States and the European Committee for Electrotechnical Standardization (CENELEC) in Europe.

To obtain certification for wire shielding, manufacturers need to undergo a thorough evaluation and testing process conducted by accredited certification bodies. The certification process typically involves verifying compliance with relevant standards, such as IEC 61000 for electromagnetic compatibility (EMC), IEC 60529 for ingress protection (IP) ratings, and various cable-specific standards like IEC 61156 for communication cables or ISO 6722 for automotive cables.

During the certification process, manufacturers are required to submit samples of their wire shielding products for testing. These tests assess the shielding effectiveness, mechanical durability, electrical performance, and compliance with specific requirements outlined in the applicable standards. Once a manufacturer's products pass the evaluation and meet the necessary criteria, they are granted certification, which serves as evidence of their compliance with the established regulatory standards and industry specifications. Certification not only demonstrates the quality and reliability of the wire shielding but also helps manufacturers gain trust and credibility in the market.

Applications of Wire Shielding

Wire shielding finds extensive applications across various industries. In the automotive sector, it is used to minimize interference in electronic systems, ensuring optimal performance of components such as infotainment systems and engine control units. In aerospace and defense, meanwhile, wire shielding is critical for safeguarding communication systems and avionics from interference, guaranteeing reliable operation in demanding environments. Medical devices also rely on wire shielding to maintain signal integrity and prevent interference that could compromise patient safety. Furthermore, telecommunications infrastructure heavily utilizes wire shielding to ensure clear and uninterrupted data transmission. Additionally, wire shielding is vital in audio and entertainment systems, reducing noise and preserving audio fidelity. Finally, industrial automation systems benefit from wire shielding by preventing EMI-induced malfunctions and maintaining reliable operation.

Choosing the Proper Wire Shielding Supplier

To ensure you have the most beneficial outcome when purchasing wire shielding from a wire shielding supplier, it is important to compare several companies using our directory of wire shielding suppliers. Each wire shielding supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each wire shielding business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple wire shielding companies with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services